This could be prevented if… – Pilz South East Asia

Sponsored Article by PILZ

Based on The Straits Times article, on June 6th, a worker was installing electrical cabling on the cable tray mounted on the third-floor wall while working at the height of approximately 7.7m on a scissor lift, a mobile elevated work platform. A crane collided with it, causing it to topple. A worker had fallen to his death because of this incident.

Pilz, is a global leader in safe automation technology headquartered in Germany with more than 70 years of expertise in the industry. Pilz deliver trendsetting innovations such as:

- the first emergency stop relay PNOZ – currently the synonym for safety relays

- the first safe camera system SafetyEYE for three-dimensional zone monitoring

- the first internationally certified qualification CMSE® that sets standards throughout the world for training in the field of machinery safety

- the award-winning, first configurable modular safety relay in batch size 1 – myPNOZ

Pilz has established its headquarters in Singapore in 2016 and now has presence in Malaysia, Thailand and Vietnam. Pilz has been awarded the Asian Manufacturing Awards for Best Machine Safety Systems Provider in 2016 & 2017.

Their safety radar sensor, PSENrd 1.2 won the best product under the Safety Category in the recent World of Safety and Health Asia Awards 2022 held in September 2022.

Pilz South East Asia had stated their point of view on this matter in an interview session with WSHAsia.

-

“At the same time, other workers were using a crane to transport rubbish bags to the first floor for disposal. The crane collided with the scissor lift, causing the platform to topple towards the floor.”

In your opinion, how could this scenario be avoided?Workplace accidents and fatalities can be avoided by ensuring proper safety measures are set in place. These safety measures are not limited to safety devices alone, but a proper risk assessment of the plant must be done to be able to identify all the danger zones at the workplace, as well as proper trainings for all personnel. For example, in this scenario, the concurrent operations and possible collision of the machines used for the said operations can be predicted, and thus avoided through a proper plant assessment. After all factors are considered, a coherent safety concept is then proposed by the safety experts and should be implemented to ensure optimised safety for their workers.

-

What does your organisation have that could have prevented such an incident?

Pilz is a leader in the field of safe automation for over 70 years now. Our key competence and indeed, our company slogan is – WE AUTOMATE, SAFELY. For Pilz, safety comes first and that is the reason why our offers are different from other automation companies in the market. We have safety products like safety relays, controllers, sensor technology, drive technology and more. Additionally, we back these products up with our safety services conducted by a team of professional safety experts which provides a holistic approach to companies that are looking for safety solutions.

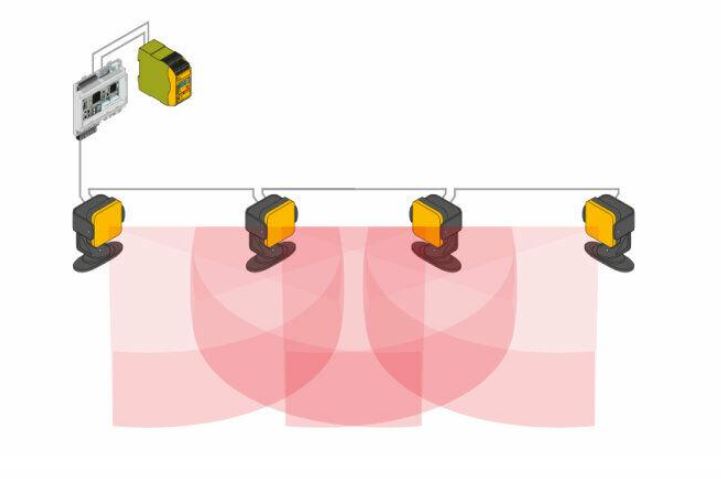

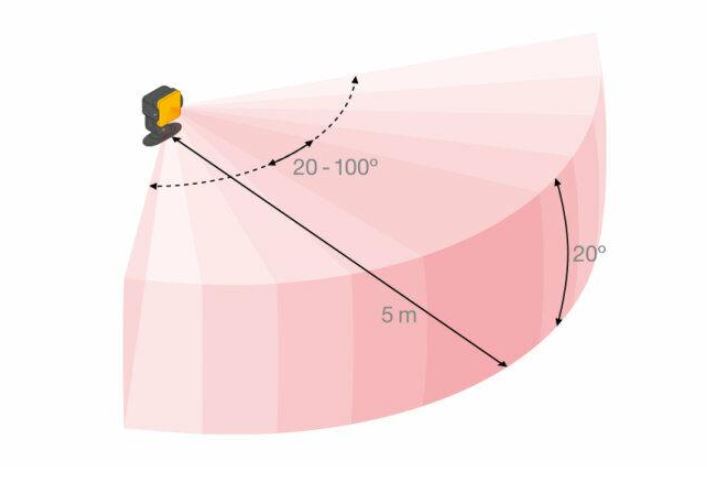

Product-wise, a specific system could be studied and applied in this scenario. The PSENradar system which consists of the safe radar sensor PSENradar, and configurable small controller PNOZmulti 2 or the modular safety relay myPNOZ. The system offers a safe and complete solution for protection zone monitoring. But of course, it all depends on the results after conducting the proper risk assessment of your plant or workplace.

-

How do you feel safety and technology go together?

The more advanced technologies get, the greater the safety concerns grow. Technology and safety often go hand in hand with the end goal of providing maximum efficiency and productivity without risking or compromising the safety of the people around these advancements. One could not go without the other. For example, robots help to reduce the process where operators are exposed to hazards. However, the robot itself may pose a different set of hazards to the operators. Hence, such risks need to be handled as well. Technology also supports advancements in safety, like the safety radar which provides a new and effective way of protecting humans in a challenging environment.

-

What other ways could you share in order to improve the level of safety?

Safety matters but often, it is a concern downplayed by many despite the global awareness it evokes. Any business with human-machine collaborations should invest in a holistic safety solution even before running its operations. This includes a proper risk assessment of a machine, the entire system or plant to validate and implement the recommended safety measures. This way, possible accidents could be predicted and thus avoided.

Machinery safety or safety training in general is another way a business can improve its level of safety. With all personnel undergoing safety trainings, they will have the essential knowledge they need to operate a machinery or the entire plant from a safety viewpoint. This highlights the importance of safety across the organization. Investing in safety is a worthwhile process that benefits both employers and employees.

-

Any other information you would like to share that would help prevent this incident or related incidents? You may share with us relevant case studies as well.

At the Antwerp bulk cargo port for fertilizer manufacturer EuroChem, items are transported via a complex network of conveyors and elevators. The connecting component is a massive conveyor that serves as a sorting mechanism. The environment is difficult in this situation since the excessively dusty discharge points need to be cleaned often and operators must constantly have easy access to the machine area. The operator must also have sufficient protection, since the belt tripper weighs several tons and is constantly in motion which poses a great risk to their safety. Today, even in these challenging (visibility) circumstances, safe and effective workflows are ensured by the safe radar system PSENradar by Pilz.

The benefits at a glance:

– In extremely rugged and contaminated production environments, the radar system represents a safe, high-performance solution

– Protection against tampering: PSENradar also detects unwanted changes in the sensors’ position

– Safe and complete solution with control technology for protection zone monitoring, including conformity assessment

Read the full success story here – Pilz SG

Mark Meng

Managing Director, Pilz South East Asia

Mark Meng has an extensive knowledge and experience in the automation and machinery industry in the ASEAN and APAC region with a strong focus on business development, strategic planning, sales management, channel partner development, and technical consultation. He’s also a subject expert in robotics, IIoT, Industrial 4.0, and machinery safety.

Kajol Manoharlal

Editor in Chief, World of Safety and Health Asia

Disclaimer: The assertions in this interview are based on the information from the Straits Times and the opinions expressed are solely based on the views of the expert. The published editorials and all other content is published in good faith. WSHAsia will not be held responsible for the content of such views nor can be held liable for any direct or indirect damage that may arise from such views.