WSHAsia: “Ask The Expert” Reviews The Case of a Worker Struck by Falling Objects at Warehouse

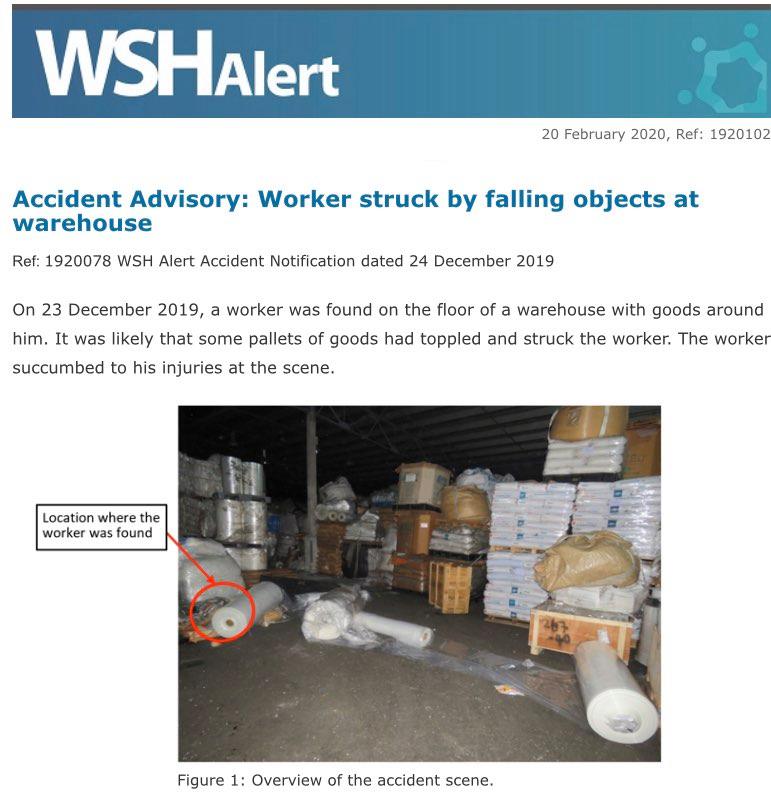

WSH Council Bulletin, reported an accident in the warehouse, where a worker was found on the floor with goods around him on the 23rd of December 2019. It was likely that some pallets of goods had toppled on the worker. The worker succumbed to his injuries at the scene.

World of Safety & Health Asia speaks to Mr. Christopher Mok, the subject matter expert in the racking safety industry to share with us on how such similar cases can be prevented with a look at safety & health solutions out in the industry.

Hi Christopher! Greetings from World of Safety & Health Asia! We would like to hear from you apart from the safe work procedures, guidelines, standards and acts that the WSH Council had mentioned. What are the solutions that are available in the industry and how are we able to prevent such cases in the future?

WSHAsia: Christopher could you share with us a little about yourself in this industry?

I started in the Storage Equipment business since 1985 (35 years), primarily design, supply and installation of storage equipment. Design storage solution for numerous MNC as well as SME warehouses. I am the first and only practicing Rack Safety Inspector with SEMA(UK) certification (with professional indemnity). We have conducted numerous Annual rack Safety Inspection (ARSI) since 2013, the ARSI is strongly prescribed by all rack manufactures, COP (worldwide), OHSAS and most safety regulatory organisation. We have structured Rack Safety & Compliance Awareness training for the warehouse users, safety officers, operation, logistic professionals and others. This training is essential for the Adjustable Pallet Rack users, as part of administrative controls. We have been Rack Safety Advocator in Asia and continue champion safe use of Adjustable Pallet Rack.

WSHAsia: What are the solutions (In terms of safety & health, products & services) you are aware of, that can help prevent such cases?

Adjustable Pallet Racking system is most commonly used equipment for past 30 odd years. The application / design of APR will be designed specific requirements with the use of Mechanical Handling Equipment (MHE). All APR design is for specific use and needs to be regularly reviewed and inspected by Rack Safety expert for rack deformation or damages. APR is a standard product manufactured and tested to meet industry Code of Practices. APR does is a fixed system resulting in safety environment.

WSHAsia: How and why do you think such solution works? (Elaborate on the implementation and effectiveness of these solutions)

Adjustable Pallet Racking (APR) is a safe and inexpensive solution, these the APR is design, tested and manufactured as a product. May application can be “off the shelf” rack, ready and safe for use. Its term Adjustable Pallet Rack describes the flexibility of system to be configured user’s requirements (safe for use to be verified). With parts of the APR are easily replaceable when damaged & deformed, maintenance cost can be controlled. Normally the APR will last more than 10 years and with regular inspection and should last past 15 year (subjective) with Annual Rack Safety Inspection. The mortality of the APR is subject to many factors, and Annual Rack safety Inspection is critically one factor.

WSHAsia: In your opinion, why are there still entities that do not use such solutions?

Basically, the most primitive storage is block stacking, it’s the cheapest and quickest solution for some business to adopt as “Temporary” storage. But such “Temporary” eventually become a permanent storage. The use of APR maybe one of the solutions to be consideration by business owners. However, the use of APR may result in reduction in the space utilization compared to the Block Stacking. This is critical when the storage space is a premium and it is even more critical when the storage space is main source of revenue for the business owner/stakeholder.

Further consideration for installation & use of APR, other equipment needs to be acquired:

- Adjustable Pallet Rack

- Mechanical Handling Equipment (MHE) to be use with APR

- Additional space required for the pallets storage – block staking 70% vs Selective Rack 20% (subjective) floor utilization

In short, the cost of implementation, deters use of APR. Another factor is ignorance as the safety in warehouse is normally overlooked.

WSH Asia: Last but not least, how do you think the related stakeholders can be encouraged to implement such solutions?

If it not legislated, means it’s not necessary to incur the business cost. This is the common reply from ignorant stakeholders, unless it is legislated stakeholder will not take necessary action to ensure safety in the warehouse.

I believe that workplace safety will be a great motivational factor coupled with Rack Safety & Compliance Awareness to help stakeholder understand safety in the warehouse.