Turning Virtual Into Reality

Sponsored Article by Nigel Taylor

Today’s demanding worksites are increasingly integrated, deadline-driven, and reliant on heavy machinery. That can lead to increased safety risks—an unfortunate trend that’s evident in the rising rates of industrial accidents and fatalities across Asia, as reported in the Asian Development Blog.

This is the problem Serious Labs is working to solve with cutting-edge virtual reality (VR) technology. Using the power of VR for assessment, training, and accreditation, this global company develops immersive simulators for heavy equipment, including the Mobile Elevating Work Platform (MEWP) VR simulator which is already being used in Singapore.

“Our business is all about helping workers become more skilled operators and getting them home safely each day,” says Nigel Taylor, Serious Labs’ European Director. “We do that by enabling them to operate machinery more safely and confidently, all in a VR environment that never puts them, the equipment, or the site at risk.”

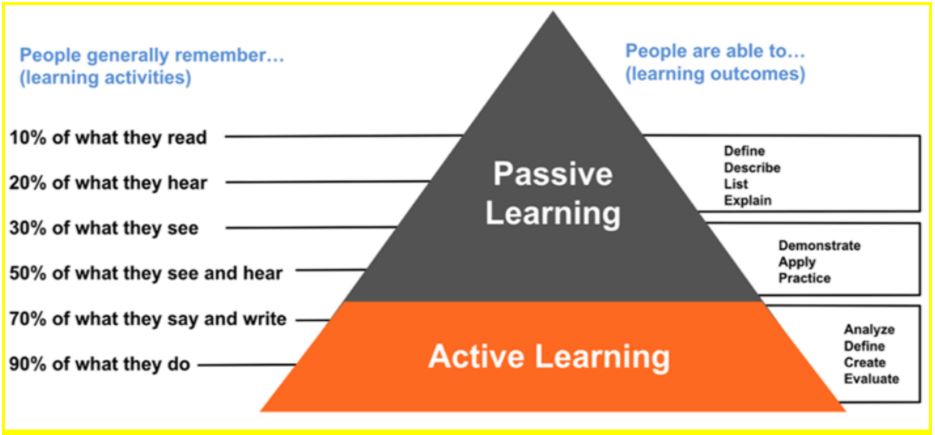

The technology works because it’s possible to learn real-life skills in VR. Studies show that learners build proficiency faster and retain more than they would with traditional classroom learning since VR is a fully immersive “active learning” experience.

“It’s very similar to how airlines train their pilots using flight simulators,” says Taylor. “When you put that headset on, suddenly you’re on a worksite, carrying out the actual tasks you’d be performing in real life. There are dozens of scenarios, from beginner to advanced; it’s a tremendous way to assess, train, and accredit an operator.”

“It’s very similar to how airlines train their pilots using flight simulators,” says Taylor. “When you put that headset on, suddenly you’re on a worksite, carrying out the actual tasks you’d be performing in real life. There are dozens of scenarios, from beginner to advanced; it’s a tremendous way to assess, train, and accredit an operator.”

While simulators have been around since the 1950s, Serious Labs is leading the charge to bring them to the heavy equipment industry. Their simulators use real-world machine controls, immersive VR headsets, and hydraulics to create authentic movement. They’ve also greatly reduced “cybersickness”—the feeling of motion sickness that VR users sometimes experience—thanks to advanced synchronization of hardware and software, where the base moves in harmony with the movement of the machine controls.

Serious Labs offers a three-in-one simulator for the boom, slab, and rough terrain scissor lifts, as well as a crane simulator developed in partnership with Industrial Training International (ITI). A forklift simulator is launching later this year.

(Pictured: a Serious Labs MEWP VR Simulator)

Building a safer industry through assessment, training, and accreditation

How do the simulators make worksites safer? “It comes down to two things: ongoing assessment and training,” says Taylor.

Assessment refers to how the simulator can evaluate an operator’s level of proficiency. As users carry out tasks on the virtual worksite, the simulator assesses them on over 130 data points—everything from where they’re looking to whether they choose the right controls and how carefully they use them, also known as feathering.

“With human assessment alone, you can never possibly capture all of those factors,” says Taylor. “Despite the best of intentions, human assessors are subjective, and we make mistakes. The simulator gives us a tool that’s always accurate and objective, and this enables like-for-like comparisons between operators and on a macro level across different worksites or subcontractors.”

Serious Labs calls its assessment “operator telematics.” Modern heavy equipment is typically fitted with telematics and the MEWP VR simulator provides the other half of the equation with in-depth information about an operator’s safety and skills. Serious Labs breaks this down with a scoring system called ESP™: Efficiency + Safety = Proficiency. It’s designed to take the results from all the data collected and convert them into an easily interpretable number out of 100.

“After running a group of workers through an assessment, you’ll be able to quickly tell who your most proficient operators are, as well as those who need targeted training,” says Taylor. “One key benefit is that you can identify poor operators in advance of them entering the worksite. Often, this includes operators who have previously obtained a MEWP license but may not have used one for some time, and their skills have lapsed. At the same time, even highly experienced operators are not immune to developing bad habits.”

Whether it’s operators whose skills have lapsed or those who’ve slipped into poor practices, the MEWP VR Simulator provides automatic recommendations for training and improvement.

What does this follow-up training look like? “The simulator provides a clear understanding of an operator’s specific skill gaps and how to address them,” says Taylor. “Follow-up training can take place on the simulator, which will tailor its training program to work on those areas. Similarly, follow-up training may take place in a classroom or on a real machine. What’s important is to spend time improving skills and shoring up the identified deficiencies.”

Above all, the goal is to instil safe, best-practice operating measures. As shown on the behaviour-based safety triangle, below, these measures help reduce unsafe behaviours and conditions, which has a cascading effect of reducing more serious incidents. “By reducing those risky behaviours at the outset, the simulator is training operators to make their whole site safer,” notes Taylor.

Another significant benefit of VR is the ability to practice and prepare for scenarios that would be too expensive or dangerous to recreate in real-life training. “It’s hard for airline maintenance workers to practice because if a MEWP accidentally hits an aircraft, the cost is eye-watering,” says Taylor. “So we’ve developed aircraft-specific scenarios and we’re working with clients like major South East Asian airlines to train their Aircraft Engineers.”

VR: A tool for a changing world

Taylor’s message for safety professionals considering VR solutions is that the time is now. “This is a technology that’s becoming increasingly common. What we’re seeing now is that it’s been refined to the point where it’s easy to use and it’s providing real benefits. We’re able to take the world’s best training centre directly to our client’s sites, which results in less downtime for operators. There’s also improved safety from a COVID-19 standpoint as operators don’t need to leave the site to receive their training.”

As employers look for ways to train workers in safe operation—especially younger generations who have grown up with technology—Taylor isn’t surprised that more and more of them are turning to VR. “It’s where the world is going. We’ve got simulators on the HS2 construction project, which is one of Europe’s largest projects and we’re seeing more and more deployments across the globe. It’s a technology that’s coming into its own.”

Taylor also thinks VR training aligns with how the world is changing. “There are more and more e-learning and remote training taking place, and the impact of COVID-19 has accelerated that. Blending theory-focused e-learning with simulator use in a controlled environment is going to be a requirement during our recovery from COVID and beyond. The time has now arrived to enhance traditional training with virtual reality, and that’s what we’re here to do.”

To learn more about Serious Labs, visit www.seriouslabs.com or email

About Serious Labs

Serious Labs is an award-winning technology company that develops virtual reality simulators for heavy equipment. Available in multiple languages and used in over a dozen countries worldwide, these ultra-realistic simulators train heavy equipment operators to work more safely and efficiently. Using the power of virtual reality, Serious Labs helps reduce industrial risks so that workers can get home safely every day.