How to Choose the Right Safety Gloves

Sponsored Article by UVEX

Safety gloves protect our hands against all kinds of hazards: from scratches and cuts to abrasion wounds, which can be caused by contact with rough metals, sharp glass, or dangerous chemicals. The safety glove market is vast, with designs in virtually any length, colour, and shape, and in a diverse range of materials with different types of coating. With so many choices, how do you know which glove is right for you? Which glove is the best option for protecting you or your employees?

1. What are the risks/hazards for the users in the workplace?

To narrow down your options from the huge selection of gloves on the market, the first thing you need to do is work out which of the four hazard categories below applies in your workplace:

● Do you need to ensure that the wearer is protected against mechanical injuries, such as scratches or abrasion wounds? If so, “Mechanical protection” is the category you’re looking for.

● There may also be a risk of cuts or even minor burns.

● There may also be a risk of cuts or even minor burns.

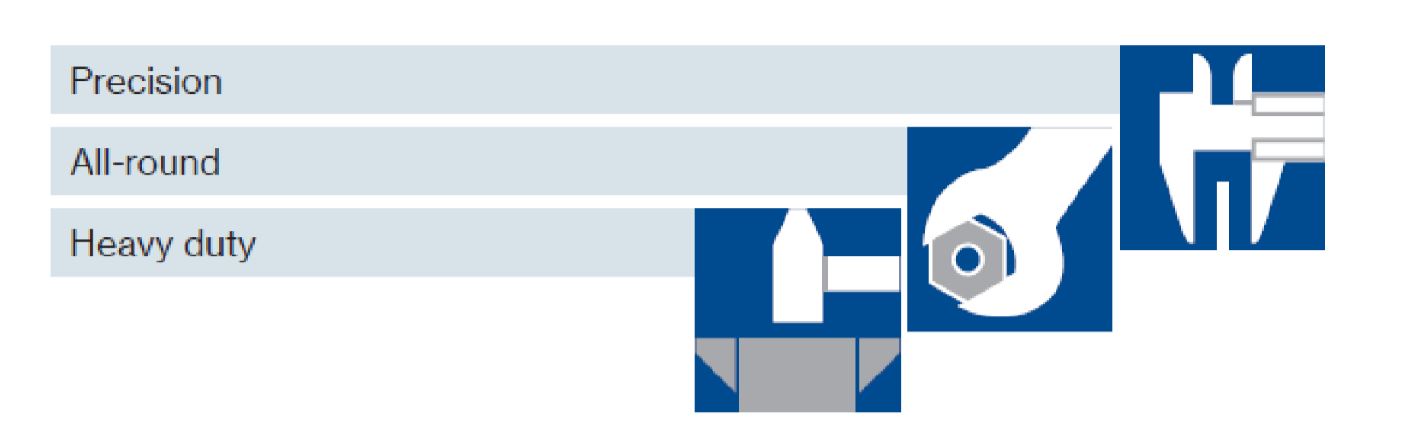

2. Determine the type of activities the safety gloves are being used for

The first step in determining the hazard category is usually an easy one – but now you need to take a closer look at your application.

For example, let’s assume that your employees are at risk of cuts and you, therefore, selected “Cut protection” in step 1: What kind of tasks are employees required to execute with their hands?

Does the work require precision and dexterity? If so, the category you need is obvious. Or do employees complete more heavy-duty tasks, such as handling panes of glass or heavy metal components with sharp edges? If so, opt for gloves from the “Heavy-duty” category – your employees will need a very robust glove.

If the activity performed by your employees is neither precision nor heavy-duty work, an All-round glove is probably your best option. These gloves can be used for general tasks and when switching between different activities that require a strong safety glove.

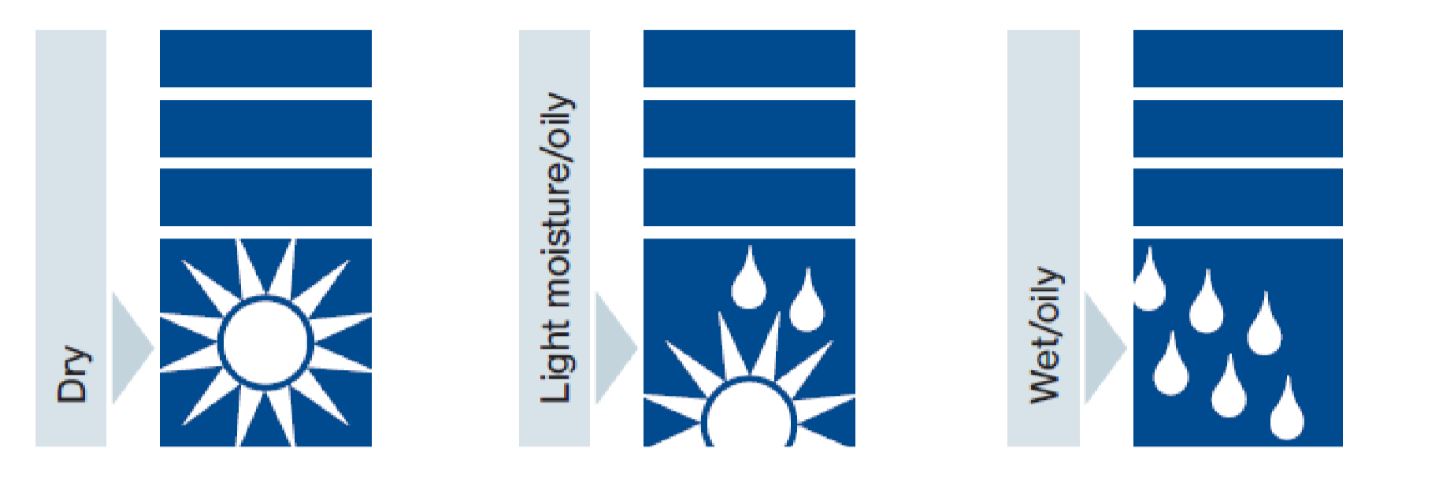

3. Defining environmental conditions.

You’re nearly ready to select the right glove for your application. There’s just one question left to answer: What are conditions like in the workplace? Will the gloves come into contact with wet or oily workpieces? If your employees handle small, sharp, and oily components, they will need a different cut protection glove as compared to people working in a completely dry environment.

The difference between these gloves lies in the coating, which will determine whether the glove is water-tight, water-resistant, or breathable.

All uvex safety gloves are categorised according to which types of environments they are suitable for: either “dry”, “damp to slightly oily” or “wet to oily”. The level indicated above each symbol tells you how suitable the glove is for each type of environment.

4. Skin-friendly and Tactile gloves

Whether a safety glove is comfortable to wear depends – literally – on both internal and external factors. On the one hand, the hands should sweat as little as possible. On the other hand, the dexterity of the fingers should be kept as high as possible. Because if a safety glove is perceived as annoying, the tendency to remove the hand protection altogether increases, resulting in a significantly higher risk of injury!

On the one hand, it’s therefore advisable to use skin-friendly safety gloves. Of course, all materials that have direct contact with the skin over long periods of time should be dermatologically tested and free of harmful substances. Test seals such as the OEKO-TEX® Standard 100 provide information about this. In addition to this seal, uvex Bamboo TwinFlex D® xg has been dermatologically tested as part of a study involving subjects with sensitive skin. This test was carried out externally by ProDERM® Institute (Institute for Applied Dermatological Research).

uvex Bamboo TwinFlex D® xg has also been awarded the ProDERM® certificate and Standard 100 by Öko-Tex. Due to the absence of vulcanisation accelerators, which are often used in nitrile coatings, it is also suitable for people with type IV hypersensitivity who are particularly prone to allergic reactions.

In the past, it was often the thickness and strength of materials that ensured a high level of cut protection. Today, on the other hand, the latest technological developments make it possible to use the finest steel and HPPE (high-performance polyethylene) to produce particularly thin safety gloves with a very high level of cut protection.

For safety gloves that offer cut protection level D, uvex Bamboo TwinFlex D® xg are amazingly light, flexible, and thin, which allows them to offer a particularly high level of sensitivity at the same time. Therefore, workers do not need significant amounts of additional energy to be able to move their hands over sustained periods of time without becoming tired. This reduces the risk of injuries and increases workplace safety.

5. Do your Safety Gloves require touchscreen capability?

More and more companies are integrating intelligent methods into their production process as part of digitalisation (Industry 4.0). The use of screens, tablets and hand-held devices with a touchscreen function is continuously rising.

It is particularly important to keep employee safety in mind in this regard. If the use of safety gloves is mandatory in areas with a cutting risk, the respective safety gloves should have touchscreen capability. This is because taking off cut protection gloves when operating touchscreen devices should be avoided. This is not only relevant in terms of safety but also requires additional time, resulting in increased costs for the company. The touchscreen capability of uvex Bamboo TwinFlex D® xg eliminates this risk as the gloves can be worn continuously.

6. Determining the performance of safety gloves

That’s easy – a glove trial. It is still the best way to evaluate the performance of your hand personal protective equipment. It’s the process of field-testing different models of safety gloves, either from a single source or from several manufacturers, to identify the best glove for a particular job.

Looking at things like comfort, usability, and applicability specific to your workers. When done correctly, the benefits of a glove trial include:

● Improved hand safety program and equipment

● Reduced rate of injuries

● Increased awareness of hand safety issues among workers

● Higher rates of compliance with hand safety PPE requirements

● Reduction in costs related to hand protection through increased efficiency and durability of work gloves, reduced insurance rates, medical costs, and workers’ compensation claims

We’ve spent years perfecting our understanding of how to help workers go home safe every day – and though it is not an exact science, we are confident that we can help you find a hand PPE solution that best fits your needs either through what is listed above or in person. If the latter, we would like to invite you to come onboard with us for a Safety Glove Trial program.

About uvex safety

As one of the top PPE suppliers established in Germany in 1926, the uvex brand is based on two established pillars – sports and safety. As a partner of elite international sport, uvex sports equips over 1,000 top athletes across the world. Everything revolves around safety at work in the uvex safetygroup, a safety equipment supplier you can trust: uvex develops, manufactures, and distributes industrial safety products that meet the highest standards in terms of quality, function, and innovation.